Add to Cart

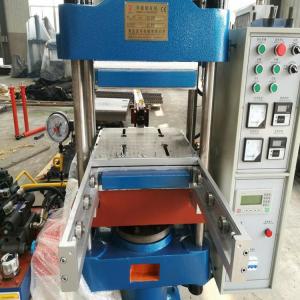

Rubber Vulcanizing Press Rubber Product Making Machinery Rubber Press Machine

The structure of the vulcanizing machine has a frame type and a four-column type. The heating forms are divided into three heating modes: electric heating, steam heating, and thermal oil heating. With automatic vulcanizing machine, automatic pressure compensation, automatic alarm device

The vulcanizer hydraulic system produced by our company has a scientific design, overall rigidity, low noise, and convenient operation. It can be controlled sequentially according to the pressure, time, speed and temperature required for different products into the PLC. Secondary exhaust to improve product quality and product yield

| Type | XLB1000×1000×2Q | XLB1200×1200×2Q | XLB1400×1500×1Q | XLB1200×2700×2Q | XLB1600×6000×1Q | XLBE-Q1200×1200 | XLBE-Q1600×1500 |

| Total pressure (MN) | 2.5 | 3.15 | 5 | 7.5 | 24 | 3.15 | 5 |

| Plate distance(mm) | 200 | 300 | 450 | 300 | 400 | 450 | 450 |

| Working layer number | 2 | 2 | 1 | 2 | 1 | 1 | 1 |

| Unit area pressure of hot plate(Mpa) | 2.50 | 2.19 | 2.38 | 2.31 | 2.50 | 2.19 | 2.08 |

| Plunger stroke(mm) | 400 | 400 | 400 | 400 | 400 | 400 | 400 |

| Heating mode | Steam/oil | Steam/oil | Steam/oil | Steam/oil | Steam | Steam/oil | Steam/oil |

| Main motor power (KW) | 5.5 | 5.5 | 11 | 18.5 | 26 | 11 | 11 |

| Overall dimension (L×W×H) (mm) | 1490×1000×2510 | 1835×1200×2600 | 2150×1500×2900 | 1780×2890×2800 | 6300×2500×3200 | 1200×1800×2140 | 1500×2400×2600 |

| Frame form | Frame | Frame | Frame | Frame | Frame | Jaw | Jaw |

QINGDAO SHENGHUALONG RUBBER MACHINERY was established in 1967,have employee more than five hundreds,

manufacturing for rubber machine and laminating machine.

As a rubber machinery manufacturer ,Hangsen has land for more than 50000 square meters, with a total assets of more than USD 100million, more than 500 employees, and 60 mechanical engineers,

The company is one of the largest private enterprises engaging in professional produce rubber machine .

We 8 meters gantry type milling machine,

TK6913B CNC boring and milling machine

TPX6213 floor boring

TPX6113 milling and boring machine

Vertical machining center

CY-K630 CNC lathe

2.5 Meters vertical lathe and other large advanced processing equipment

We mainly produce following machinery.

Radial tire equipment

XK-660 Rubber open mixing mill

42 to 65.5 inch double mold vulcanizing machine

75-105 inch single mold vulcanizing machine

Internal mixer series, Rubber mixing mill series, Extrusion and filter series

Tyre tube, flap, inner tube plate vulcanizing machine

Waste tire recycling line

Rubber reclaim sheet line and so on,

We can also design and manufacture for various non-standard rubber machinery and equipment according to the customers requirement.

Our company always follows the market concept of “Market demand first , Customer first.

Till now,We have exported to more than 40 countries,enjoy a good reputation in the world market.